PRODUCT PARAMETERS

Description

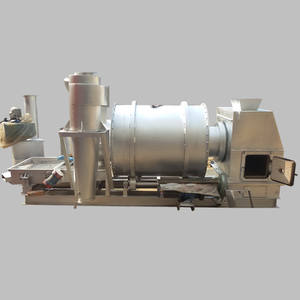

Introduction to Energy saving small rotary dryer Silica Sand Dryer for Corn Bran Rotary Grain Dryer

Energy saving small rotary dryer Silica Sand Dryer for Corn Bran Rotary Grain Dryer is for repairing, replacing or upgrading worn, damaged or deteriorated parts in drying equipment. These spare parts can include heating elements, drums, belts, fans, temperature and humidity controls, etc., to ensure that the dryer will run efficiently and consistently.

Advantages and features of Energy saving small rotary dryer Silica Sand Dryer for Corn Bran Rotary Grain Dryer

High-quality materials: manufactured using durable and heat-resistant materials to ensure long life and high reliability.

Precise Fit: Precisely designed for specific models of dryers to ensure easy installation and perfect fit.

Rapid Response: Provide fast spare parts supply service to reduce downtime and improve production efficiency.

Technical Support: Equipped with a professional technical support team to provide installation guidance and troubleshooting assistance.

Cost-effectiveness: Reduce long-term operating costs by extending the service life of the equipment.

(Energy saving small rotary dryer Silica Sand Dryer for Corn Bran Rotary Grain Dryer)

Specifications of Energy saving small rotary dryer Silica Sand Dryer for Corn Bran Rotary Grain Dryer

This small rotary clothes dryer conserves energy drying out silica sand, corn bran, grains, and comparable products. It deals with smaller sized batches efficiently. Its portable design fits well in limited spaces. The rotating drum tumbles materials constantly. This activity makes sure also warm direct exposure. Warm air moves with the drum efficiently. Products completely dry quicker by doing this.

Warmth sources are versatile. You can use electricity, natural gas, propane, or biomass fuels. This choice aids match your regional power expenses. The drum indoor functions unique lifters. These lifters lift and cascade the product. This activity makes best use of call with the warm air. Warmth transfer boosts dramatically. Drying time shortens. Energy use lowers.

The outer shell utilizes quality stainless steel. This construction stands up to corrosion. It makes certain long service life. Good insulation twists around the drum. This layer catches heat inside. Less heat leaves right into the environments. Gas consumption decreases. Operating costs remain low.

Temperature level control is accurate. Operators readjust warmth setups quickly. This prevents overheating sensitive products like corn bran. Different materials need certain drying out temperature levels. This dryer deals with those variations. Air flow within the drum is adjustable. Proper air flow removes wetness properly. Final product dampness web content meets precise demands.

Safety and security attributes are integrated. Temperature level sensing units check conditions constantly. Overheating threats are decreased. Drive systems are trusted. They offer consistent drum turning. Maintenance accessibility factors are hassle-free. Cleansing and servicing are straightforward jobs.

(Energy saving small rotary dryer Silica Sand Dryer for Corn Bran Rotary Grain Dryer)

Applications of Energy saving small rotary dryer Silica Sand Dryer for Corn Bran Rotary Grain Dryer

This energy saving small rotary clothes dryer takes care of difficult drying out jobs well. It dries out silica sand perfectly. Silica sand requires exact moisture control for numerous uses. Factories use dry sand for molds. Glass makers need really completely dry sand too. Building makes use of dry sand in concrete and mortar. This rotary dryer hits the ideal dampness level every time. Its special style conserves a lot of power. It makes use of warm air wisely. This reduces your fuel prices. The machine is solid and lasts long. It runs non-stop without issues. Operators regulate the drying out quickly.

The same clothes dryer functions great for corn bran and other grains. Farms and feed mills need completely dry bran. Dry bran shops safely. It stops mold and waste. This machine dries out bran delicately. It maintains the bran’s nutrients. The warm doesn’t shed the bran. The drum turns slowly. This mixes the bran uniformly. Dampness comes out quickly. You obtain constant outcomes set after batch. The tiny dimension fits several places. It functions well in tight spots. Arrangement is simple and fast. Upkeep is very easy too. Employees learn to run it fast. It saves you money and time.

The rotating action is key. Products tumble inside the drum. Hot air streams via them. This get in touch with dries out things quick. The internal trips lift and go down the product. This reveals all surface areas to warmth. Wetness leaves efficiently. The system uses warmth well. Less heat gets squandered. Your operating costs remain reduced. You get trustworthy drying performance. Dampness degrees are specific. Product top quality is high every time. This machine is a solid option for silica sand and grain bran drying out. It supplies trustworthy results day in day out.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Energy saving small rotary dryer Silica Sand Dryer for Corn Bran Rotary Grain Dryer

What makes this rotary dryer save energy?

It uses indirect heat transfer. Hot air flows around the material inside the rotating drum. This method traps heat better. Less heat escapes into the air outside. Your fuel costs drop significantly. It also dries materials faster. Less running time means less power used overall.

How does this dryer handle different materials like silica sand and corn bran?

The drum rotates gently. This tumbles the material constantly. Hot air surrounds every particle evenly. Silica sand needs thorough drying. Corn bran needs gentle handling to avoid burning. The adjustable rotation speed and temperature settings work for both. You get consistent dryness without damaging fragile grains.

Why is indirect heating better for grains?

Grains like corn bran are sensitive. Direct flame contact risks scorching. Indirect heating uses hot air only. The material never touches open flame or hot metal surfaces. This keeps the corn bran’s quality high. The taste and nutritional value stay intact. It’s a safer method for food products.

Is this dryer safe to operate?

Safety features are built in. Temperature sensors monitor the heat constantly. If things get too hot, the system adjusts automatically. Overheat protection shuts things down if needed. Sturdy construction prevents leaks. Reliable seals keep dust inside the drum. Operators stay safe from high heat and dust hazards.

What maintenance does this dryer need?

Routine checks keep it running smoothly. Inspect the drum seals regularly. Clean the air intake filters often. Blocked filters make the fan work harder. Lubricate the rotation bearings as the manual says. Check the heating elements or burner yearly. Basic care prevents big breakdowns. It ensures long life and efficient drying.

(Energy saving small rotary dryer Silica Sand Dryer for Corn Bran Rotary Grain Dryer)

REQUEST A QUOTE

RELATED PRODUCTS

Low Rotary scratch drum dryer for food

3-5t/h rotary paddy dryer sludge rotary drum dryer for sand drying plant

Industrial Rotary Drying Machine Slag River Sand Rotary Drum Cooling Dryer Machine

High Speed Industry Food Rotating Drum Wet Powder Mixing Vacuum Dryer Double Conical Double Cone rotary Dryer Drying Machine

Vacuum dryer Glass lined rotary dryer vacuum shaking can dryer