PRODUCT PARAMETERS

Description

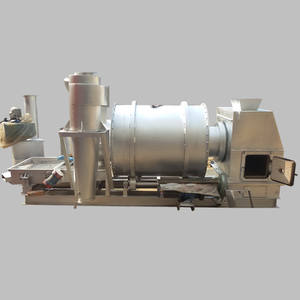

Introduction to 304 Stainless Steel Rotary Drum Flaker Dryer Drying Equipment in Food Chemical Industry

304 Stainless Steel Rotary Drum Flaker Dryer Drying Equipment in Food Chemical Industry is for repairing, replacing or upgrading worn, damaged or deteriorated parts in drying equipment. These spare parts can include heating elements, drums, belts, fans, temperature and humidity controls, etc., to ensure that the dryer will run efficiently and consistently.

Advantages and features of 304 Stainless Steel Rotary Drum Flaker Dryer Drying Equipment in Food Chemical Industry

High-quality materials: manufactured using durable and heat-resistant materials to ensure long life and high reliability.

Precise Fit: Precisely designed for specific models of dryers to ensure easy installation and perfect fit.

Rapid Response: Provide fast spare parts supply service to reduce downtime and improve production efficiency.

Technical Support: Equipped with a professional technical support team to provide installation guidance and troubleshooting assistance.

Cost-effectiveness: Reduce long-term operating costs by extending the service life of the equipment.

(304 Stainless Steel Rotary Drum Flaker Dryer Drying Equipment in Food Chemical Industry)

Specifications of 304 Stainless Steel Rotary Drum Flaker Dryer Drying Equipment in Food Chemical Industry

This 304 stainless steel rotary drum flaker dryer handles drying and cooling jobs in food and chemical production. It uses high-grade 304 stainless steel throughout. This material fights corrosion well. It meets strict hygiene rules for food safety. The equipment is built tough for demanding daily use.

The core part is a large, rotating drum. The drum has thick stainless steel walls. Steam or electric heat warms the drum surface evenly. Wet material feeds onto the hot drum. A thin layer forms instantly. Heat moves into the material fast. Moisture turns to vapor quickly. The dried material flakes off the drum surface. A sharp knife scrapes the flakes cleanly. Steam escapes through vents fast. This process gives precise moisture control.

The drum spins steadily. Bearings support the drum ends strongly. A sturdy frame holds everything solidly. Drive systems use reliable motors and gearboxes. Speed adjusts easily. Different materials need different drum temperatures. Operators set the heat accurately. They control the material feed rate too. They adjust the drum speed. This flexibility handles many products.

Sanitary design is critical. Smooth surfaces prevent material sticking. Easy access points allow thorough cleaning. No moving parts are inside the drum. This avoids contamination risks. Maintenance stays simple. Seals are effective. They keep the process contained. This design is vital for food and sensitive chemicals.

The equipment dries pastes, slurries, and thick liquids efficiently. It cools hot flakes effectively too. Consistent product quality is key. Uniform flakes are the result. Low energy use is a major benefit. The machine runs reliably for years. It handles sticky or abrasive materials fine. This makes it a core tool for many factories.

(304 Stainless Steel Rotary Drum Flaker Dryer Drying Equipment in Food Chemical Industry)

Applications of 304 Stainless Steel Rotary Drum Flaker Dryer Drying Equipment in Food Chemical Industry

304 stainless steel rotary drum flaker dryer drying equipment is very important in the food and chemical industries. This equipment dries liquid or paste materials into solid flakes. It uses a big rotating drum heated inside. The material spreads thinly on the drum’s hot surface. The water evaporates quickly. A knife scrapes the dried material off as a thin flake. The flakes are easy to handle and store.

This dryer uses 304 stainless steel. This material is key. It resists rust very well. Food and chemical materials are often wet or acidic. They can attack metal. 304 stainless steel handles this. It keeps the product clean and safe. It also makes the equipment last longer. This saves money over time.

In the food industry, this dryer makes many products. It dries milk into powder. It makes instant mashed potato flakes. It creates fruit purees into sheets. It processes starches like corn or potato. It dries yeast extracts. The high heat kills germs. The stainless steel surface is easy to clean. This is vital for food safety rules.

The chemical industry uses this dryer too. It dries many chemical pastes and slurries. It makes flakes from dyes and pigments. It processes mineral salts. It handles detergent mixtures. It dries certain resins. The equipment handles different materials well. The corrosion resistance protects against harsh chemicals. This prevents product contamination. It also avoids equipment damage.

The rotary drum flaker dryer offers good control. Operators can adjust the drum’s heat. They can change the drum’s speed. They can adjust the feed rate. This controls the drying speed. It controls the final flake thickness. This flexibility is useful. Different products need different settings. The result is consistent, high-quality flakes every time.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of 304 Stainless Steel Rotary Drum Flaker Dryer Drying Equipment in Food Chemical Industry

What makes 304 stainless steel good for food and chemical dryers?

304 stainless steel resists rust well. It handles common food acids and many chemicals safely. This material prevents contamination. It meets strict food safety rules. Cleanup is easy too.

How does this dryer actually dry things?

Wet material goes into the rotating drum. Hot air flows through the drum. The material tumbles inside. Moisture turns to vapor. The vapor gets carried away by the air. The drum spins constantly for even drying.

Can it handle different temperatures?

Yes, it handles a wide temperature range. You set the heat based on your material. Control systems keep the temperature steady. This is vital for sensitive products. It prevents damage from getting too hot.

Is this machine hard to maintain?

Not really. The drum rotation is simple. Few moving parts exist. Seals and bearings need regular checks. Good daily cleaning prevents buildup. Proper operation avoids most problems. It runs reliably for a long time.

Does it dry stuff efficiently?

Yes, it works very efficiently. The tumbling action exposes all material surfaces. Hot air contacts the material directly. Moisture removal happens quickly. This saves energy. It saves money on drying costs.

(304 Stainless Steel Rotary Drum Flaker Dryer Drying Equipment in Food Chemical Industry)

REQUEST A QUOTE

RELATED PRODUCTS

2019 ISO9001 & CE Approved Cow Manure Rotary Drying Machine/Chicken Manure Dryer

Electric heating drying equipment rotary drum dryer Drum Automatic Electric Heating Dryer Calcination

Best Rotary Drum Dryer for Coal Slime/Kaolin/Fertilizer/Lime/Slag/Sand

sawdust kaolin clay drying apparatus/rotary dryer

China s Commercial Laundry Machinery 20 kg Reliable Rotary Cylinder Clothes Dryer Drying Machine Tumble Dryer for