PRODUCT PARAMETERS

Description

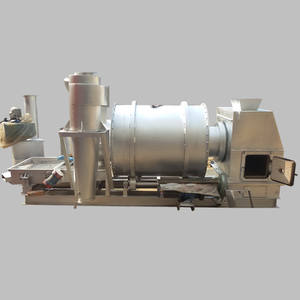

Introduction to Small Sand Rotary Drum Sawdust Dryer Machine

Small Sand Rotary Drum Sawdust Dryer Machine is for repairing, replacing or upgrading worn, damaged or deteriorated parts in drying equipment. These spare parts can include heating elements, drums, belts, fans, temperature and humidity controls, etc., to ensure that the dryer will run efficiently and consistently.

Advantages and features of Small Sand Rotary Drum Sawdust Dryer Machine

High-quality materials: manufactured using durable and heat-resistant materials to ensure long life and high reliability.

Precise Fit: Precisely designed for specific models of dryers to ensure easy installation and perfect fit.

Rapid Response: Provide fast spare parts supply service to reduce downtime and improve production efficiency.

Technical Support: Equipped with a professional technical support team to provide installation guidance and troubleshooting assistance.

Cost-effectiveness: Reduce long-term operating costs by extending the service life of the equipment.

(Small Sand Rotary Drum Sawdust Dryer Machine )

Specifications of Small Sand Rotary Drum Sawdust Dryer Machine

This small sand rotary drum sawdust dryer machine handles drying tasks effectively. It suits smaller production needs well. The core component is the rotating drum. This drum is made from strong steel. Its size is compact for space-saving. You can load wet sand or sawdust directly into this drum. The drum turns steadily during operation. This turning action mixes the material constantly. Good mixing promotes even drying.

Heat comes from a reliable burner system. This burner uses common fuels like gas or diesel. Hot air flows into the rotating drum. The hot air contacts the wet material directly. Heat transfers from the air to the material. Moisture evaporates due to the heat. A powerful fan pulls the moist air out. This fan maintains steady airflow through the drum. Good airflow is crucial for efficiency. The machine has basic control settings. You adjust temperature and drum speed easily. These controls help manage the drying rate. Simple operation makes it user-friendly.

The machine frame is welded steel. This ensures solid support. The drum rotates on durable bearings. These bearings handle the load reliably. Drive comes from an electric motor. The motor connects through a gearbox. This setup provides steady drum rotation. Guards protect moving parts for safety. Maintenance is straightforward. Access points allow for easy cleaning. You need to check parts periodically. Proper care extends the machine’s life.

Drying time depends on material moisture. It also depends on the desired final dryness. Output capacity fits smaller batches. You get consistently dried sand or sawdust. The dried product has low moisture content. This machine meets basic drying requirements reliably.

(Small Sand Rotary Drum Sawdust Dryer Machine )

Applications of Small Sand Rotary Drum Sawdust Dryer Machine

This small sand rotary drum sawdust dryer machine tackles moisture in many materials. It works well for small businesses and workshops. You feed wet material into one end of the rotating drum. Hot air flows through the drum. This hot air absorbs moisture from the material as it tumbles. The dried material comes out the other end ready for use. This process happens continuously.

This dryer handles more than just sawdust. It dries many granular or powdery substances effectively. Sawdust is a common material dried this way. Dry sawdust burns better. It’s essential for making wood pellets or briquettes. Dry sand is crucial too. Construction projects need dry sand for concrete or mortar. Wet sand causes problems. The dryer ensures sand is properly dried.

Wood chips benefit from drying before processing. Dry chips work better in chippers or for fuel. This machine dries various biomass wastes efficiently. Think about rice husks or straw. Drying these makes them useful fuel sources. Mineral powders often need drying too. This dryer handles them. It helps prepare minerals for further processing or packaging.

The machine is compact. It fits well in limited spaces. Its rotary drum design ensures even drying. The tumbling action exposes all material to the hot air. This prevents clumping. Heat sources vary. You can use gas, oil, or even waste heat. This offers flexibility. The machine is simple to operate. Maintenance is straightforward. It provides reliable drying for different industries. This makes it a versatile tool.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Small Sand Rotary Drum Sawdust Dryer Machine

What is a Small Sand Rotary Drum Sawdust Dryer Machine?

This machine dries wet sand or sawdust. It uses a rotating drum. Hot air flows through the drum. The tumbling action exposes the material to heat evenly. This removes moisture effectively. It turns wet material into dry, usable product fast.

What materials can this dryer handle?

It mainly handles sand and sawdust. It works best with granular materials. These materials flow easily inside the rotating drum. Very fine powders or sticky substances might not work well. They could cause blockages. Always check if your specific material is suitable.

How long does drying take?

Drying time varies. It depends on several things. How wet the material is initially matters a lot. The type of material affects it too. The temperature of the hot air is important. The airflow speed inside the drum plays a role. Generally, it processes batches relatively quickly compared to other methods.

What provides the heat?

The heat source can be different. Common options include electricity, gas, or biomass fuel. The choice depends on your setup and costs. Electric heaters are often used. Gas burners offer high heat. Biomass is a cheaper option where available. The hot air is blown into the drum.

Why choose this type of dryer?

This dryer is efficient. It handles drying well for its size. The rotary action ensures even drying. This prevents hot spots. The machine is robust. It’s built to last. It saves time and money on drying large amounts of sand or sawdust. Consistent results are expected.

(Small Sand Rotary Drum Sawdust Dryer Machine )

REQUEST A QUOTE

RELATED PRODUCTS

70L Easy Operation hot air dryer drying machine Centrifugal Spin Drying Machine

35L New Batch Industrial Belt Dryer Machine Vacuum Food Dryer centrifugal dryer machine

New SUS304L Rotary Drum Dryer Three Types for Food Processing and Manufacturing Plant Rotary Drying Equipment

High Efficiency Industrial Dryer Rotary Drum Dryer, Enenry Saving Copper Concentrate Drying Production Line/Rotary Dryer

0.5-1tph New Environmental Design Small Rotary Drum Dryer Electric Rotary Dryer for