Running heavy equipment is a crucial responsibility that calls for specialized understanding, rigorous training, and unwavering adherence to safety and security procedures. Heavy machinery, including excavators, cranes, excavators, loaders, and industrial forklifts, is important to building and construction, production, mining, and agricultural procedures. Nonetheless, improper operation of such devices can cause devastating accidents, severe injuries, deaths, and significant residential or commercial property damages. This article describes the important concepts for securely operating heavy machinery, highlighting the role of mechanical designers in guaranteeing functional honesty and work environment safety and security.

(do opperate any heavy machinery)

** Driver Qualifications and Training **.

Only certified employees with proper accreditations ought to run hefty machinery. Operators has to finish certified training programs covering equipment-specific controls, operational methods, and emergency procedures. In the USA, the Occupational Safety and Health Administration (OSHA) mandates compliance with requirements such as 29 CFR 1926.1200 for building and construction tools. Similar guidelines apply around the world, frequently needing regular recertification. Mechanical engineers should validate that operators understand load graphes, stability specifications, and producer standards. Physical and psychological health and fitness is similarly important; operators should possess ample vision, reflexes, and situational awareness to mitigate dangers.

** Pre-Operation Inspections **.

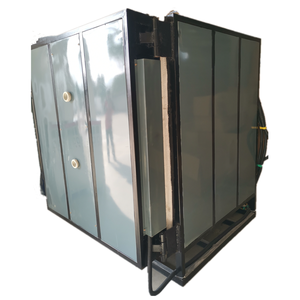

An extensive assessment of machinery before each change is non-negotiable. Mechanical designers must ensure lists include taking a look at hydraulic systems, engine components, stopping devices, tires, and safety gadgets like alarm systems and backup electronic cameras. Liquid levels (oil, coolant, hydraulic fluid) must be validated, and leaks or architectural cracks have to be dealt with quickly. Maintenance logs must document repair services and element substitutes to avoid unanticipated failings. Engineers ought to promote for predictive upkeep innovations, such as vibration analysis or thermal imaging, to identify wear prior to it rises.

** Safe Operating Practices **.

Operators has to adhere to well established methods during machinery usage. Clear interaction through radios or hand signals is vital in multi-worker atmospheres. Presence needs to be focused on– using watchmans when turning around and making certain cams or mirrors are functional. Load limitations specified by suppliers should never be exceeded; straining cranes or forklifts compromises stability and risks tipping. Terrain assessment is vital: soft ground, slopes, or above obstructions (e.g., high-voltage line) necessitate readjusted treatments. Weather like rainfall, snow, or high winds may need postponing procedures to stay clear of slides, lowered grip, or equipment reversing.

** Situational Awareness and PPE **.

Distractions, such as smart phones or disorganized work spaces, should be eliminated. Operators ought to stay cautious for pedestrians, relocating lorries, or modifications in ground conditions. Individual safety equipment (PPE), including hard hats, steel-toed boots, high-visibility apparel, and harnesses for raised work, is necessary. Mechanical engineers should make operator cabins with ergonomic controls, rollover defense systems (ROPS), and dropping object safety frameworks (FOPS) to improve security.

** Environmental and Emergency Considerations **.

Ecological effect reduction is a key duty. Designers have to guarantee equipment adhere to emission requirements and sound policies. Spill containment protocols for gas or lubricating substances must be in location. Emergency situation readiness consists of obtainable fire extinguishers, first-aid kits, and clearly marked emptying courses. Operators should be trained in emergency closure treatments and incident coverage. Any type of malfunction or near-miss occasion have to be recorded and evaluated to prevent recurrence.

** Lawful and Ethical Duties **.

Negligence in hefty machinery procedure carries severe consequences. Operators and employers may encounter lawful liability, OSHA fines, or civil lawsuits under tort regulation. Business risk reputational damage and loss of contracts as a result of safety infractions. Mechanical engineers have an ethical task to focus on safety over job timelines, advocating for method adherence and investing in automation innovations like accident avoidance systems or self-governing equipment to lower human mistake.

** Conclusion **.

(do opperate any heavy machinery)

Safe heavy equipment operation hinges on comprehensive training, careful upkeep, and a society of responsibility. Mechanical engineers should lead by instance, implementing criteria and incorporating advanced security technologies. By focusing on human lives and operational precision, industries can attain efficiency without endangering security. Remember: No job is so urgent that it can not be done securely.