PRODUCT PARAMETERS

Description

Introduction to China Factory Drum Dryer Sand Dryer Small Rotary Dryer For Sawdust Coal Heating

China Factory Drum Dryer Sand Dryer Small Rotary Dryer For Sawdust Coal Heating is for repairing, replacing or upgrading worn, damaged or deteriorated parts in drying equipment. These spare parts can include heating elements, drums, belts, fans, temperature and humidity controls, etc., to ensure that the dryer will run efficiently and consistently.

Advantages and features of China Factory Drum Dryer Sand Dryer Small Rotary Dryer For Sawdust Coal Heating

High-quality materials: manufactured using durable and heat-resistant materials to ensure long life and high reliability.

Precise Fit: Precisely designed for specific models of dryers to ensure easy installation and perfect fit.

Rapid Response: Provide fast spare parts supply service to reduce downtime and improve production efficiency.

Technical Support: Equipped with a professional technical support team to provide installation guidance and troubleshooting assistance.

Cost-effectiveness: Reduce long-term operating costs by extending the service life of the equipment.

(China Factory Drum Dryer Sand Dryer Small Rotary Dryer For Sawdust Coal Heating)

Specifications of China Factory Drum Dryer Sand Dryer Small Rotary Dryer For Sawdust Coal Heating

China Manufacturing Facility Drum Dryer Sand Clothes Dryer Small Rotary Clothes Dryer For Sawdust Coal Heating offers trusted efficiency for commercial drying out needs. The maker is constructed with premium products to take care of hard problems. It benefits drying out sand, sawdust, coal, and similar products. The rotating drum design makes sure also heat distribution for regular outcomes.

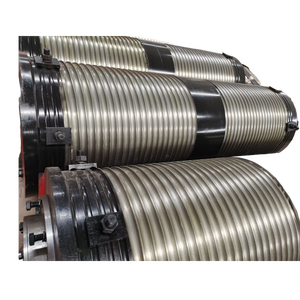

The drum is made from durable stainless steel to resist deterioration and wear. The heater makes use of coal, wood, or gas for adaptability. The temperature changes conveniently to match different products. A thermostat manages warm degrees automatically to stop overheating. This saves power and keeps operation prices low.

The portable structure fits tiny to medium production spaces. The machine runs smoothly with marginal resonance or noise. An electric motor powers the rotating drum for steady material activity. The internal fins lift and spread products to enhance drying performance. Hot air flows via the drum to get rid of dampness rapidly.

Operation is simple with straightforward controls. The user interface shows temperature level, speed, and drying out time clearly. Safety and security attributes include overload security and emergency quits. Upkeep is easy due to obtainable parts and straightforward cleaning steps. The maker lasts much longer with regular checks and lubrication.

Personalization is offered for drum size, home heating techniques, and power levels. The factory tests each unit to ensure top quality prior to shipment. Technical assistance is attended to setup and troubleshooting. Spare components are equipped for fast substitutes if needed.

This dryer functions well in building and construction, farming, mining, and biomass handling. It dries out sand for concrete mixing efficiently. Sawdust comes to be suitable for fuel pellets after drying. Coal wetness drops for far better burning. The device manages damp or clumpy materials without obstructing.

The factory concentrates on long lasting designs and cost-effective solutions. Affordable pricing fulfills budget needs without reducing corners. Orders deliver worldwide with secure product packaging and documents. Manufacturing deadlines are satisfied to stay clear of job delays.

Consumers select this dryer for its dependability and flexibility. It fits into existing assembly line efficiently. Performance remains steady under hefty workloads. The design minimizes dust exhausts for a cleaner work area.

(China Factory Drum Dryer Sand Dryer Small Rotary Dryer For Sawdust Coal Heating)

Applications of China Factory Drum Dryer Sand Dryer Small Rotary Dryer For Sawdust Coal Heating

China manufacturing facility drum dryers sand dryers tiny rotating clothes dryers serve lots of practical uses across sectors. These machines take care of materials like sand sawdust coal successfully. Their layout concentrates on high heat transfer sturdiness making them trusted for durable operations.

Drum dryers work well for drying out bulk materials in building and construction mining sectors. They process damp sand quickly getting rid of moisture to generate dry sand all set for concrete production. The turning drum style makes sure even heating up prevents clumping. This conserves time decreases power prices compared to traditional drying out methods.

Sand dryers concentrate on managing big quantities of building sand. They preserve constant temperatures to avoid over-drying secure material top quality. Manufacturing facilities utilize them to prepare sand for glassmaking factory work. The robust framework handles unpleasant materials without wear ensures lengthy life span.

Small rotating clothes dryers adjust to smaller sized areas lighter work. They dry sawdust wood chips efficiently for biomass gas manufacturing. Uniform drying stops mold and mildew growth boosts burning performance. Farms reusing centers depend on these devices to process organic waste into usable gas resources.

Coal heating systems in these dryers provide economical warmth remedies. They burn coal easily produce consistent temperatures for industrial drying needs. This suits areas with limited gas or electricity access. Factories reduce fuel expenses while preserving efficiency.

These equipments feature easy to use controls low upkeep requirements. Operators change rate temperature conveniently match various material requirements. Basic layouts lessen failures reduce repair work expenses. Secured chambers protect against dust leak meet environmental standards.

China manufacturing facilities generate drum dryers sand clothes dryers rotary dryers with sophisticated innovation competitive pricing. Personalized sizes arrangements fit specific project needs. Global customers resource these devices for their reliability affordability. Industries benefit from faster handling times higher output quality.

Drum clothes dryers deal with challenging conditions rough products without performance loss. Heat-resistant interiors corrosion-resistant exteriors endure prolonged usage. This makes them perfect for 24/7 procedures in demanding settings.

Services looking for effective drying out options find these machines useful financial investments. They simplify process reduced functional costs sustain sustainable practices.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of China Factory Drum Dryer Sand Dryer Small Rotary Dryer For Sawdust Coal Heating

China Factory Drum Dryer Sand Dryer Small Rotary Dryer For Sawdust Coal Heating: 5 FAQs

1. How does the drum dryer work?

The drum dryer rotates materials inside a heated cylinder. Heat comes from coal, gas, or electricity. Wet materials like sand or sawdust tumble inside. Hot air removes moisture. Dry materials exit through the discharge end. The process is continuous.

2. What materials can this dryer handle?

It works for sawdust, coal, sand, and similar granular or powdery substances. High moisture content is acceptable. The drum’s design prevents clogging. Heavy-duty construction handles abrasive materials. Avoid sticky or oversized items.

3. How often does the dryer need maintenance?

Check seals and bearings every 3-6 months. Clean the drum after each use. Lubricate moving parts monthly. Replace worn components immediately. Regular upkeep prevents breakdowns. Professional servicing is advised yearly.

4. Is the dryer energy-efficient?

Yes. Insulated walls reduce heat loss. Adjustable temperature settings match material needs. Coal heating offers low fuel costs. Efficient airflow shortens drying time. Proper operation cuts energy waste.

5. What safety features are included?

Overload protection stops the drum if jammed. Temperature sensors prevent overheating. Emergency shut-off switches are accessible. Ventilation removes dust and fumes. Operators must wear protective gear. Fire risks are minimized with proper use.

These answers address common concerns. Users should follow guidelines for best results.

(China Factory Drum Dryer Sand Dryer Small Rotary Dryer For Sawdust Coal Heating)

REQUEST A QUOTE

RELATED PRODUCTS

Best Industrial Rotary Drum Dryer for Sludge Seed Drier Coal Powder Drying Equipment

High Quality Rotary Dryer And Rotary Drum Dryer Plant for Coal Sludge

Industrial Silica Sand Browncoal Wood Sawdust Three Drums Dryer Rotary Drum Rotating Dryer Machine For

High-quality Pet Food Corn Drying Rotary Drum Dryer Machine from HENAN KELEFU

70L Economic equipment centrifugal dryer machine/metal Parts Drying and Deoiling Machine