PRODUCT PARAMETERS

Description

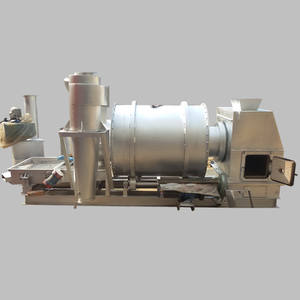

Introduction to Drum Dryer Flaker Rotary Dryer For Drying Industry Drum Dryer For Canldes

Drum Dryer Flaker Rotary Dryer For Drying Industry Drum Dryer For Canldes is for repairing, replacing or upgrading worn, damaged or deteriorated parts in drying equipment. These spare parts can include heating elements, drums, belts, fans, temperature and humidity controls, etc., to ensure that the dryer will run efficiently and consistently.

Advantages and features of Drum Dryer Flaker Rotary Dryer For Drying Industry Drum Dryer For Canldes

High-quality materials: manufactured using durable and heat-resistant materials to ensure long life and high reliability.

Precise Fit: Precisely designed for specific models of dryers to ensure easy installation and perfect fit.

Rapid Response: Provide fast spare parts supply service to reduce downtime and improve production efficiency.

Technical Support: Equipped with a professional technical support team to provide installation guidance and troubleshooting assistance.

Cost-effectiveness: Reduce long-term operating costs by extending the service life of the equipment.

(Drum Dryer Flaker Rotary Dryer For Drying Industry Drum Dryer For Canldes)

Specifications of Drum Dryer Flaker Rotary Dryer For Drying Industry Drum Dryer For Canldes

Drum dryer flakers and rotary dryers handle tough drying jobs in many industries. These machines dry materials effectively. They work especially well for candle production. This equipment dries waxes and other candle ingredients reliably. The core design involves a large steel drum. This drum rotates slowly. Heat gets applied inside the drum. Materials needing drying go onto the drum’s outer surface. Heat transfers directly through the drum wall. The material dries quickly as the drum turns. A thin layer sticks to the hot surface. This layer dries almost instantly. A scraper knife then removes the dried product. The product usually flakes off. This gives the “flaker” part of the name.

These dryers handle pastes, slurries, and sticky substances easily. They are perfect for liquid or semi-solid feeds. The process is continuous. Material feeds in one end constantly. Dry product comes out the other end constantly. Operators control the drying rate precisely. They adjust the drum rotation speed. They control the heating medium temperature. They manage the material feed rate. This gives excellent control over the final product moisture. Energy efficiency is a major benefit. Direct contact heating minimizes heat loss. The large surface area allows rapid evaporation. This saves operating costs.

Drum dryers work well for heat-sensitive materials. The short contact time prevents damage. The product only touches the hot surface briefly. This is vital for candle waxes. It preserves their quality and melting point. The dried output is usually a thin flake or powder. This form is easy to handle. It stores well. It flows freely for further processing. Common heating sources include steam, hot oil, or hot water. Steam is most frequent. It provides consistent, controllable heat. Robust construction ensures long service life. These machines handle demanding industrial environments. Low maintenance needs are another advantage. Simple design means fewer parts can break.

(Drum Dryer Flaker Rotary Dryer For Drying Industry Drum Dryer For Canldes)

Applications of Drum Dryer Flaker Rotary Dryer For Drying Industry Drum Dryer For Canldes

Drum dryers are essential in many drying processes. They work well for drying candle materials. Drum dryers handle liquid waxes effectively. The liquid wax spreads onto a heated rotating drum. Heat transfers quickly through the drum surface. The wax dries very fast. It solidifies into a thin film. A scraper knife peels this dry film off the drum. The dry wax breaks into flakes or chips. This flake form is perfect for candle making.

Flaker rollers are often part of the system. They help shape the dried wax. The wax gets pressed into consistent flakes or sheets. This shape makes storage and handling easy. It also melts evenly later during candle production. Drum dryers are very efficient. They use less energy than some other dryers. Their compact design saves valuable factory floor space. They dry materials continuously. This means constant output for candle factories.

Drum dryers handle heat-sensitive materials well. They prevent damage to delicate waxes. The temperature control is precise. Operators can adjust the drum heat carefully. This ensures the wax dries correctly. It avoids burning or degrading the material. The process keeps the wax’s important properties. Drum dryers are also reliable. They need less maintenance than many systems. Downtime is minimal. This keeps candle production lines running smoothly.

Rotary dryers are another option. They work differently. Wet material tumbles inside a rotating cylinder. Hot air flows through the cylinder. This dries the material as it moves. Rotary dryers suit bulkier candle additives. Think herbs or granular scents mixed into wax. They handle larger volumes well. Both drum and rotary dryers are vital tools. They meet different needs within the candle industry. Choosing the right dryer depends on the specific material. Factors include its form, sensitivity, and required final dryness.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Drum Dryer Flaker Rotary Dryer For Drying Industry Drum Dryer For Canldes

What is a drum dryer flaker rotary dryer?

This machine dries wet materials using a heated rotating drum. It turns liquids or pastes into dry flakes. Industries use it for products like candle wax. The drum heats up. Material spreads thinly inside. Moisture evaporates. Dry flakes scrape off easily.

How does it dry candle materials?

Candle wax mixtures enter the drum. Hot air or steam heats the drum surface. The mixture spreads into a thin layer. It dries fast. Flakes form as the drum rotates. A blade scrapes dried flakes out. The process is continuous. It handles large batches quickly.

Why choose this dryer for candle production?

It dries wax evenly. Flakes cool down fast. This keeps wax properties stable. The machine uses heat efficiently. It saves energy. Flakes mix better with dyes or scents later. Production speeds up. Output quality stays consistent.

What size or type fits candle makers?

Pick a drum size matching your output needs. Small workshops need compact dryers. Big factories need high-capacity models. Check heating options: steam, gas, or electric. Steam suits large setups. Electric works for smaller ones. Ensure the drum material resists wax sticking. Stainless steel is common.

How to maintain the drum dryer?

Clean the drum after each batch. Remove leftover wax scraps. Check the scraper blade often. Replace it if worn. Lubricate bearings monthly. Inspect seals for leaks. Fix leaks fast to save heat. Schedule professional checks yearly. Proper care prevents breakdowns. It extends machine life.

(Drum Dryer Flaker Rotary Dryer For Drying Industry Drum Dryer For Canldes)

REQUEST A QUOTE

RELATED PRODUCTS

Industrial Sand Rotary Dryer Three Layer Rotary Dryer Rotary Drum Dryer

Three-Cylinder Rotary Dryer New Type Rotary Dryer Rotary Vane Vacuum Pump Freeze Dryer Vacuum Pump

Industrial silica sand Browncoal wood sawdust rotary drum dryer machine, three cylinders drum dryer

Rotary vacuum rake dryer Organic solvent drying equipment ZB series vacuum rake dryer

35L New Batch Industrial Belt Dryer Machine Vacuum Food Dryer centrifugal dryer machine