PRODUCT PARAMETERS

Description

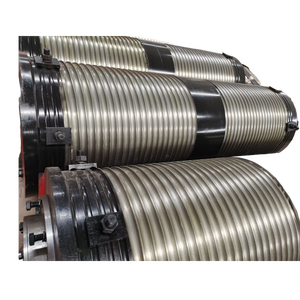

Introduction to High Quality Rotary Dryer/Drum Dryer for Drying Sand/Stone

High Quality Rotary Dryer/Drum Dryer for Drying Sand/Stone is for repairing, replacing or upgrading worn, damaged or deteriorated parts in drying equipment. These spare parts can include heating elements, drums, belts, fans, temperature and humidity controls, etc., to ensure that the dryer will run efficiently and consistently.

Advantages and features of High Quality Rotary Dryer/Drum Dryer for Drying Sand/Stone

High-quality materials: manufactured using durable and heat-resistant materials to ensure long life and high reliability.

Precise Fit: Precisely designed for specific models of dryers to ensure easy installation and perfect fit.

Rapid Response: Provide fast spare parts supply service to reduce downtime and improve production efficiency.

Technical Support: Equipped with a professional technical support team to provide installation guidance and troubleshooting assistance.

Cost-effectiveness: Reduce long-term operating costs by extending the service life of the equipment.

(High Quality Rotary Dryer/Drum Dryer for Drying Sand/Stone)

Specifications of High Quality Rotary Dryer/Drum Dryer for Drying Sand/Stone

Top notch rotary dryers efficiently manage drying out sand and rock. These makers process materials quickly. They maintain consistent warmth levels. The drum style makes certain even drying out. Sturdy steel building and construction gives toughness. High temperatures do not harm the framework. The drum turns gradually. This protects against material clumping. Warm distribution remains consistent. Customized dimensions match manufacturing demands. Small procedures utilize portable versions. Huge sectors select heavy-capacity units. The drying out process conserves power. Advanced insulation lowers heat loss. Fuel alternatives include gas, coal, or electricity. Individuals choose based upon schedule and expense. Automatic temperature control streamlines procedure. Sensing units monitor inner problems. Changes happen in genuine time. Overheating risks go down dramatically. Reduced upkeep style cuts downtime. Stainless steel parts resist wear. Bearings and gears go through rigorous screening. Long service life is ensured. Security features safeguard workers. Emergency situation quit buttons are accessible. Dust elimination systems keep air clean. Operators follow ecological requirements. Setup needs very little configuration. Clear guidelines assist assembly. Technical assistance teams help from another location. Routine checks make certain peak efficiency. Cleansing the drum avoids deposit buildup. Applications cover construction and mining markets. Sand for concrete gains optimum wetness degrees. Rock materials completely dry before further handling. These dryers integrate right into existing lines. Upgrades enhance outcome without extra room. Trustworthy efficiency suits harsh problems. Operating costs stay reduced in time. Services see fast rois. Customer responses highlights regular results. Testing confirms wetness web content accuracy. Warranties cover major elements. Spare parts are readily offered. Training programs educate secure use.

(High Quality Rotary Dryer/Drum Dryer for Drying Sand/Stone)

Applications of High Quality Rotary Dryer/Drum Dryer for Drying Sand/Stone

High-grade rotary clothes dryers, also called drum dryers, are developed to handle challenging drying out work for materials like sand and rock. These devices function well in building, mining, and commercial settings. They eliminate moisture quickly, maintaining production smooth and effective.

Rotating dryers utilize heated air inside a rotating drum to dry materials. The drum spins, moving sand or stone through hot air streams. This setup makes sure even drying without exaggerating warm. The procedure cuts dampness levels to meet market standards.

These clothes dryers are excellent for building and construction jobs. Sand utilized in concrete or asphalt needs to be completely dry for mixing. Wet sand creates delays. Rotating dryers fix this by drying out big sets quickly. They handle harsh products like smashed stone without breaking down. Mining operations use them to dry minerals prior to processing. This action is crucial for quality control.

Farming and chemical sectors additionally profit. Farmers completely dry plants much faster with rotating dryers. Factories use them to prep basic materials for manufacturing. The makers adjust to various products by adjusting temperature level and drum rate. This versatility conserves time and energy.

Rotating clothes dryers are constructed to last. Heavy-duty steels and heat-resistant components deal with heats and unpleasant materials. Maintenance is straightforward. This reduces downtime and repair service costs. The layout includes safety features to stop getting too hot or material jams.

Energy effectiveness matters. Modern rotating clothes dryers recycle heat from exhaust air. This cuts fuel costs. They operate on gas, electrical power, or biomass, suitable different center requirements. Reduced power use implies smaller environmental influence.

Product high quality remains constant. Dry sand or rock moves better in assembly line. No clumping or irregular dampness. This improves end product integrity. Dirt control systems maintain work areas tidy. They satisfy air high quality guidelines also.

These dryers work in harsh problems. Rainfall, dust, or extreme temperatures don’t slow them down. Their tough develop makes sure year-round procedure. Factories and mines count on them for stable outcome.

Rotary clothes dryers are a sensible option for heavy-duty drying. They increase performance, cut expenses, and keep products in leading shape. Services throughout markets trust them for trusted, reliable performance.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of High Quality Rotary Dryer/Drum Dryer for Drying Sand/Stone

What does a high-quality rotary dryer do?

A rotary dryer dries sand, stone, or similar materials by rotating a heated drum. The rotation spreads materials evenly inside. Hot air flows through the drum, removing moisture quickly. This method ensures consistent drying results for industrial use.

What materials can a drum dryer handle?

These dryers work best for sand, stone, gravel, and minerals. They handle small particles to medium-sized chunks. The drum’s design prevents materials from clumping. High heat tolerance makes it suitable for heavy-duty drying tasks.

How energy-efficient are rotary dryers?

Modern rotary dryers use advanced insulation to trap heat. Efficient airflow systems reduce energy waste. Burners or heaters adjust heat levels based on material type. This cuts fuel costs while maintaining high drying speeds.

What maintenance is needed for a rotary dryer?

Check the drum seals and bearings weekly for wear. Clean the interior after each use to prevent residue buildup. Inspect heating elements monthly for damage. Regular lubrication of rotating parts ensures smooth operation.

Are rotary dryers safe for industrial use?

Safety features include temperature sensors to prevent overheating. Emergency stop buttons halt operations immediately. Sturdy construction reduces vibration and noise risks. Proper training ensures operators follow safety protocols during use.

(High Quality Rotary Dryer/Drum Dryer for Drying Sand/Stone)

REQUEST A QUOTE

RELATED PRODUCTS

2906084200 IMD260 air compressor spare part atlas copco Rotary drum dryer Overhaul service Maintenance kit B

Rotary vacuum rake dryer Organic solvent drying equipment ZB series vacuum rake dryer

Rotary Dryer 500kg Double Drum Rotary Dryer Mini Rotary Drum Dryer

series Synthetic rotary vacuum dryer double conical vacuum dryer

Factory Industrial 1 To 20 Tons Per Hour Sawdust Rotary Dryer