PRODUCT PARAMETERS

Description

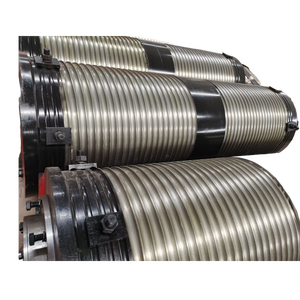

Introduction to New Type Energy Saving Industrial Drying Equipment Rotary Drum Dryer

New Type Energy Saving Industrial Drying Equipment Rotary Drum Dryer is for repairing, replacing or upgrading worn, damaged or deteriorated parts in drying equipment. These spare parts can include heating elements, drums, belts, fans, temperature and humidity controls, etc., to ensure that the dryer will run efficiently and consistently.

Advantages and features of New Type Energy Saving Industrial Drying Equipment Rotary Drum Dryer

High-quality materials: manufactured using durable and heat-resistant materials to ensure long life and high reliability.

Precise Fit: Precisely designed for specific models of dryers to ensure easy installation and perfect fit.

Rapid Response: Provide fast spare parts supply service to reduce downtime and improve production efficiency.

Technical Support: Equipped with a professional technical support team to provide installation guidance and troubleshooting assistance.

Cost-effectiveness: Reduce long-term operating costs by extending the service life of the equipment.

(New Type Energy Saving Industrial Drying Equipment Rotary Drum Dryer)

Specifications of New Type Energy Saving Industrial Drying Equipment Rotary Drum Dryer

The brand-new energy-saving commercial drying out devices Rotating Drum Clothes dryer provides high effectiveness and sturdiness for heavy-duty applications. It is built with a turning drum made of thick stainless-steel. The drum’s diameter varies from 1.5 to 3.5 meters, and its size extends in between 8 and 20 meters. This design allows large volumes of material to completely dry equally. The device operates at temperature levels from 100 ° C to 600 ° C, flexible based on product kind. Home heating methods consist of electric, gas, or vapor, providing adaptability for different industrial setups.

The clothes dryer uses sophisticated warmth recuperation technology. Excess heat from the exhaust is recycled back into the system. This cuts power usage by up to 30% compared to standard designs. Power intake stays listed below 50 kW per hour also at maximum tons. The rotation rate of the drum is flexible in between 3 and 10 RPM. This control prevents over-drying or irregular outcomes. A completely secured structure lessens warmth loss throughout operation.

Materials refined can be powders, granules, or lumps with wetness material up to 25%. The drying cycle finishes in 20 to 90 minutes depending on product residential or commercial properties. The equipment handles approximately 5 lots of product per set. Its motor works on a 380V three-phase power supply. Safety and security functions include automated temperature level closure and stress relief valves.

Upkeep is simplified with easy-access assessment ports and wear-resistant parts. The outer covering is shielded to reduce surface temperature level. Sound levels remain under 75 dB throughout procedure. Installment needs a flat concrete base and standard electric or gas connections.

The clothes dryer integrates with existing assembly line by means of conveyor belts or pneumatic systems. Sensing units keep track of dampness degrees in actual time. Operators readjust settings via a touchscreen control board. Remote surveillance is possible via IoT connection.

This devices satisfies ISO 9001 and CE accreditations. It decreases carbon exhausts by enhancing gas effectiveness. Personalized sizes and arrangements are readily available for specialized industrial requirements.

(New Type Energy Saving Industrial Drying Equipment Rotary Drum Dryer)

Applications of New Type Energy Saving Industrial Drying Equipment Rotary Drum Dryer

The new energy-saving industrial drying tools rotary drum dryer takes care of lots of products in different markets. It works well for wet or sticky substances like minerals, plant foods, biomass, and sludge. The drum turns to spread out products uniformly while warm air moves via them. This cuts drying time and maintains product high quality consistent. Warm stays inside the system due to insulation layers and secured designs. This decreases power waste and reduces operating expense.

Mining and metallurgy markets utilize this dryer to procedure ores, sands, and concentrates. It removes wetness effectively despite having high warmth needs. Agricultural organizations completely dry crops, pet feed, or food waste quickly without losing nutrients. Chemical plants depend on it for drying out powders, granules, or chemical results. The equipment changes temperature level and rate to match product demands.

Building industries completely dry raw materials like clay, crushed rock, or concrete blends. The drum’s big ability takes care of heavy lots without reducing. Manufacturing facilities with restricted room take advantage of its small style. Maintenance stays simple due to the fact that components are very easy to access and tidy. Sensors keep an eye on humidity and temperature level immediately. Alerts inform employees if setups drift from targets. This stops overheating or under-drying.

The dryer makes use of less gas or power compared to older models. Warm recovery systems recycle warm air from the exhaust. This reduces energy use by up to 30%. Less exhausts satisfy environmental policies and assistance green production. Companies conserve cash while meeting manufacturing due dates.

Personalized arrangements are offered for special material types or operations demands. Additional attributes include fire security controls, dust elimination filters, or sound reduction panels. The equipment works in severe conditions such as high moisture or dirty locations. Long lasting materials like stainless-steel or wear-resistant finishes extend the equipment’s life-span. Training and technical assistance ensure smooth procedure from day one.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of New Type Energy Saving Industrial Drying Equipment Rotary Drum Dryer

What is a rotary drum dryer used for?

This equipment dries materials like grains, minerals, or sludge in industries. It uses a rotating drum to move materials evenly while hot air removes moisture. The process suits bulk materials needing consistent drying.

How does it save energy?

The design improves heat use. Hot air stays inside longer, reducing heat loss. Advanced insulation keeps temperatures stable. Sensors adjust heat based on material moisture, avoiding wasted energy.

What maintenance does it need?

Check seals and bearings monthly to prevent leaks or friction. Clean the drum weekly to avoid blockages. Inspect heaters and fans yearly for wear. Basic upkeep keeps it running smoothly.

Can it handle different materials?

Yes. Adjust rotation speed and temperature for each material. Wet sludge needs low speed and high heat. Grains dry faster with higher speed and moderate heat. Settings adapt to various needs.

Is it safe for workers?

Safety features include temperature controls to prevent overheating. Emergency stops halt the drum instantly. Dust collection systems reduce airborne particles. Operators must follow guidelines for safe use.

(New Type Energy Saving Industrial Drying Equipment Rotary Drum Dryer)

REQUEST A QUOTE

RELATED PRODUCTS

0.5-1tph New Environmental Design Small Rotary Drum Dryer Electric Rotary Dryer for

30t/h Rotary Sand Dryer With CE Certification/Factory mining ore drying equipment

Whole Dryer Machine Replacement Parts Dryer Drum Support Roller Kit W10314173 Dryer Accessories

Single-Layer Rotary Dryer Industrial Rotary Drum Dryer Rotary Dryer Parts

Factory Direct Rotary Flaker High Quality Drum Roller Crystallizer Equipment Industrial Food Pastry Yeast Scraper Dryer