PRODUCT PARAMETERS

Description

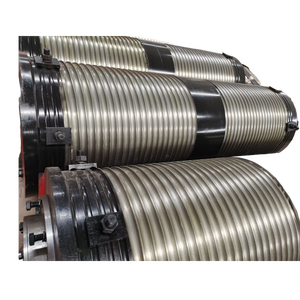

Introduction to Rotary Drum Dryer For Electromagnetic Heating mineral

Rotary Drum Dryer For Electromagnetic Heating mineral is for repairing, replacing or upgrading worn, damaged or deteriorated parts in drying equipment. These spare parts can include heating elements, drums, belts, fans, temperature and humidity controls, etc., to ensure that the dryer will run efficiently and consistently.

Advantages and features of Rotary Drum Dryer For Electromagnetic Heating mineral

High-quality materials: manufactured using durable and heat-resistant materials to ensure long life and high reliability.

Precise Fit: Precisely designed for specific models of dryers to ensure easy installation and perfect fit.

Rapid Response: Provide fast spare parts supply service to reduce downtime and improve production efficiency.

Technical Support: Equipped with a professional technical support team to provide installation guidance and troubleshooting assistance.

Cost-effectiveness: Reduce long-term operating costs by extending the service life of the equipment.

(Rotary Drum Dryer For Electromagnetic Heating mineral)

Specifications of Rotary Drum Dryer For Electromagnetic Heating mineral

These rotary drum clothes dryers utilize electro-magnetic heating particularly for drying mineral materials. They properly remove wetness from various minerals. The drums come in different sizes. Usual diameters range from 1 meter to over 3 meters. Sizes commonly range from 6 meters up to 20 meters or even more. Dimension depends straight on your needed drying out ability and manufacturing objectives.

The core function is the electro-magnetic induction heater. This system creates warm directly inside the drum wall surface. It prevents traditional outside burners. This method provides far better energy effectiveness. Warm transfers straight to the mineral material inside. It minimizes heat loss usual in various other systems. The electromagnetic field strength is flexible. This gives precise control over the drying temperature level. Operators set the exact temperature level needed for different mineral types.

Drying out happens as the drum turns. Mineral feed goes into one end. Interior trips lift and topple the product frequently. This reveals all fragments uniformly to the warmed drum surface. Warm air flows with the drum. It lugs away the released wetness vapor. The mix of direct get in touch with warmth and hot air ensures thorough, consistent drying out. Turning speed is variable. You readjust it to manage the product’s home time inside the drum. This makes certain the item gets to the exact moisture degree you need.

These clothes dryers handle numerous mineral kinds. They function well for sand, clay, ore concentrates, plaster, sedimentary rock, and comparable materials. Final dampness web content is regularly low. Result ability scales with the drum size and power input. Common abilities range from a couple of loads per hour for smaller sized devices to over 50 tons per hour for big commercial designs. The electromagnetic system is robust. It calls for less upkeep than fuel-based systems. Energy prices are lower because of the reliable heat transfer technique.

(Rotary Drum Dryer For Electromagnetic Heating mineral)

Applications of Rotary Drum Dryer For Electromagnetic Heating mineral

Rotating drum clothes dryers making use of electro-magnetic heating deal with difficult mineral drying out tasks well. This devices dries damp mineral materials successfully. The drum turns slowly. Materials roll within. Effective magnetic fields warm the drum straight. This warmth transfers quickly to the minerals relocating through the drum. Water vaporizes swiftly. This technique is extremely effective.

Electro-magnetic heating uses big benefits for minerals. It conserves substantial energy contrasted to older warm air systems. The warmth begins best inside the drum wall. Less heat leaves uselessly. This straight home heating means faster drying out times. You obtain more product dried out each hour. Temperature control is also really precise. Operators conveniently readjust the heat level. This is important for minerals sensitive to high temperatures. Some minerals alter or break down if overheated. Precise electromagnetic heat avoids this damages.

Many different minerals work well with this clothes dryer kind. It handles metal ores like iron ore or copper concentrate before smelting. Industrial minerals like quartz sand, clay, and sedimentary rock dry efficiently. Chemical salts and plant foods also dry effectively in this manner. The rolling action separate globs. Materials dry evenly. You obtain a constant, free-flowing dry item. This is vital for the next handling steps.

This innovation is strong and reliable for constant mineral handling. It takes care of high quantities regularly. Mining procedures utilize it extensively. Chemical plants rely on it for mineral preparations. Mineral processing facilities set up these dryers for trustworthy efficiency. The electro-magnetic system lowers fuel expenses significantly. Upkeep needs are typically lower also.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Rotary Drum Dryer For Electromagnetic Heating mineral

Question: How does electromagnetic heating work in a rotary drum dryer?

Answer: The system uses electromagnetic coils outside the drum. These coils create a magnetic field. This field heats the drum’s metal shell directly. The heat transfers inside to dry the minerals. It avoids heating the air first. This method is very direct.

Question: Why choose electromagnetic heating over gas or steam?

Answer: Electromagnetic heating is much more efficient. It puts heat exactly where needed, the drum wall. Less heat escapes into the air. This saves a lot of energy. It also gives better temperature control. You get lower operating costs this way.

Question: Can this dryer handle different mineral types?

Answer: Yes, it handles many minerals well. The key is setting the right drum temperature and rotation speed. You adjust these based on the mineral’s moisture and properties. The electromagnetic system controls temperature very precisely. This precision works for clays, sands, ores, and similar materials.

Question: How well does it control drying temperature?

Answer: Temperature control is excellent. Sensors monitor the drum surface temperature constantly. The system adjusts the electromagnetic power instantly. This keeps the heat steady. Steady heat prevents mineral damage. It ensures consistent product quality batch after batch.

Question: Is maintenance harder with electromagnetic heating?

Answer: Actually, maintenance is often simpler. There are no burners or complex fuel systems inside. The main parts are the electromagnetic coils and controls outside the drum. These parts need checking and cleaning. But the internal drum sees less wear overall. This design reduces downtime risks.

(Rotary Drum Dryer For Electromagnetic Heating mineral)

REQUEST A QUOTE

RELATED PRODUCTS

2024 2TPH TDOSA Rotary Drum Tumble Dryer For Okara Bean Pulp Cassava Dregs Distiller Spent Grain From

Multifunctional Laboratory Rotary Drum Dryer For Chemical Industry

Factory Direct s Dryer Machine Wood Rotary / Rotary Drum Dryer / Double Cone Vacuum Dryer

GT Series Rotary Drum Dryer GMP

Industrial silica sand Browncoal wood sawdust rotary drum dryer machine, three cylinders drum dryer