PRODUCT PARAMETERS

Description

Introduction of Mining mineral processing and cement Rotary Dryer roller press rotary Roller Kiln Bearing

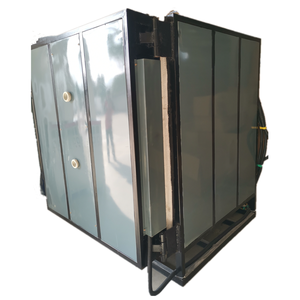

A rotary kiln is a kind of industrial equipment used for material heating and processing, which is widely used in cement, metallurgy, chemical industry, etc. Mining mineral processing and cement Rotary Dryer roller press rotary Roller Kiln Bearing refers to various parts and components which are necessary for maintaining and repairing the normal operation of the rotary kiln, such as cylinder, baffle wheel, pallet, sealing device and so on.

Features and advantages of Mining mineral processing and cement Rotary Dryer roller press rotary Roller Kiln Bearing

High-temperature resistance: Due to the extremely high temperature of the working environment of the rotary kiln, the spare parts are usually made of refractory materials or special alloys to ensure that they can work stably under high temperatures.

High abrasion resistance: Long time material friction and chemical erosion require spare parts to have excellent abrasion resistance to prolong service life.

High structural strength: in order to withstand heavy loads and the pressure of continuous operation, the design of spare parts will place special emphasis on structural strength and reliability.

Easy to install and maintain: Considering the need for frequent replacement, many spare parts are designed to be simpler and easier for quick installation and maintenance.

Strong adaptability: different industries have different needs for rotary kilns, so spare parts need to have good versatility and adaptability to meet diverse application conditions.

(Mining mineral processing and cement Rotary Dryer roller press rotary Roller Kiln Bearing)

Specifications of Mining mineral processing and cement Rotary Dryer roller press rotary Roller Kiln Bearing

Our bearings deal with tough jobs in mining, mineral processing, and concrete plants. They function inside rotary dryers, roller presses, and rotating kilns. These devices deal with extreme problems. Our bearings are built to last.

We utilize special materials. Chrome steel makes the bearing rings and rolling aspects strong. This material battles wear effectively. Warm is a big trouble. Our bearings deal with very heats consistently. They keep functioning when things fume.

Hefty lots are constant. Roller presses put in massive squashing forces. Rotating kilns bring substantial weight turning gradually. Our bearings take care of these heavy lots dependably. They protect against breakdowns.

Dirt and dirt are anywhere. Contamination ruins common bearings. Our seals are added challenging. They keep harmful fragments out. This protection expands birthing life significantly.

Lubrication is important. These bearings need the ideal grease consistently. We design them for very easy grease access. Some make use of unique oil systems. Proper lubrication reduces rubbing. It stops getting too hot.

We know every equipment is various. Standard remedies frequently fail. We customize bearings for your particular tools. We consider your clothes dryer, press, or kiln design. We check out your operating rate. We inspect your tons needs. We ask about your temperature level range. We learn about your dust levels. Then we make the perfect bearing for you.

Our objective is simple. We make bearings that run much longer. They decrease unanticipated quits. They reduced maintenance expenses. They enhance your production uptime. Select bearings made for the genuine challenges of mining and concrete.

(Mining mineral processing and cement Rotary Dryer roller press rotary Roller Kiln Bearing)

Applications of Mining mineral processing and cement Rotary Dryer roller press rotary Roller Kiln Bearing

Hefty machinery in mining, mineral handling, and concrete plants faces harsh conditions. Rotary dryers deal with wet materials under extreme heat. Roller presses squash rock with enormous stress. Rotary kilns cook basic materials at severe temperature levels. These makers require bearings that endure. Dust is everywhere. It grinds right into surfaces. Warm warps steel. Heavy loads cause continuous stress. Vibration drinks elements loose. Common bearings stop working quickly here. Downtime costs money. Manufacturing quits.

Our bearings are built for this. They take care of the high temperatures inside kilns and dryers. Unique products withstand heat distortion. Seals are critical. They keep abrasive dirt and slurry out. Our seals are difficult and multi-layered. Lubrication needs to function under stress and heat. We make use of innovative oils. They last longer and protect better. Roller presses exert squashing pressure. Bearings take huge radial loads. Our layouts manage this stress. They stop very early exhaustion and fracturing. Vibration is a continuous adversary. It loosens up fittings and puts on parts. Our bearings absorb shock. They maintain precise alignment.

Rotating devices requires smooth rotation. Friction triggers wear and power loss. Our bearings minimize friction. This conserves power and lowers heat. Lengthy service life issues. Replacing bearings is pricey and stops production. Our bearings last longer. This reduces upkeep prices and downtime. Reliability is non-negotiable. A stopped working bearing stops the whole line. We make certain consistent performance. Our bearings keep devices running. They handle the dirt, the warm, the stress. Production depends upon hard, dependable components. Our bearings supply that toughness.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Mining mineral processing and cement Rotary Dryer roller press rotary Roller Kiln Bearing

Here are 5 FAQs about Mining, Mineral Processing, and Cement Rotary Dryer, Roller Press, and Rotary Kiln Bearings:

What causes bearing failure in high-heat equipment like rotary kilns? Extreme heat expands metal parts. Standard bearings can’t handle this expansion. They seize up or wear out fast. Our bearings use special heat-resistant steel. They also have larger internal clearances. This allows for thermal growth without damage.

How do you protect bearings from harsh dust in dryers and crushers? Dust and grit destroy bearings quickly. Standard seals often fail. We use heavy-duty, double-labyrinth seals. These seals create a complex path. Dust finds it very hard to get inside. This keeps the bearing grease clean. Clean grease means longer bearing life.

Why do roller press bearings need such high load capacity? Roller presses crush rock with immense force. This force pushes directly onto the bearings. Standard bearings crack under this pressure. Our bearings feature extra-large rollers. They use tougher steel alloys. This design handles the crushing loads reliably. It prevents premature breakdowns.

What happens if bearing alignment is wrong on large rotating drums? Poor alignment puts uneven stress on the bearing. It causes excessive vibration. This vibration damages the bearing housing. It also strains the drive components. Correct alignment is critical. We provide precise mounting surfaces. Our design ensures the bearing sits perfectly straight. This maximizes equipment uptime.

How important is lubrication for these heavy-duty bearings? Proper lubrication is absolutely vital. These bearings run hot under heavy loads. The wrong grease breaks down fast. Insufficient grease causes metal-to-metal contact. We specify high-temperature, extreme-pressure greases. Our bearing housings include reliable automatic lubrication systems. Consistent, clean grease supply is essential for long bearing life.

(Mining mineral processing and cement Rotary Dryer roller press rotary Roller Kiln Bearing)

REQUEST A QUOTE

RELATED PRODUCTS

50TPD Lime Stone Calcination Rotary Kiln 100-1000TPD Lime Rotary Kiln Equipment with Customization Design

Environmental Waste Incineration Rotary Kiln

New Construction Rotational Kiln Rotary Kiln Wheel Block Custom Processing Lime Zinc Oxide Aluminum Ash Roasting Aluminum Ash

OEM rotary kiln girth gear alignment and Pinion Assembly For Rotary Kilns And Coolers

High Quality Rotary Kiln Cement Plant Drum Parts Gear Ring