PRODUCT PARAMETERS

Description

Introduction of China 200 T/d Activated Lime Rotary Kiln

A rotary kiln is a kind of industrial equipment used for material heating and processing, which is widely used in cement, metallurgy, chemical industry, etc. China 200 T/d Activated Lime Rotary Kiln refers to various parts and components which are necessary for maintaining and repairing the normal operation of the rotary kiln, such as cylinder, baffle wheel, pallet, sealing device and so on.

Features and advantages of China 200 T/d Activated Lime Rotary Kiln

High-temperature resistance: Due to the extremely high temperature of the working environment of the rotary kiln, the spare parts are usually made of refractory materials or special alloys to ensure that they can work stably under high temperatures.

High abrasion resistance: Long time material friction and chemical erosion require spare parts to have excellent abrasion resistance to prolong service life.

High structural strength: in order to withstand heavy loads and the pressure of continuous operation, the design of spare parts will place special emphasis on structural strength and reliability.

Easy to install and maintain: Considering the need for frequent replacement, many spare parts are designed to be simpler and easier for quick installation and maintenance.

Strong adaptability: different industries have different needs for rotary kilns, so spare parts need to have good versatility and adaptability to meet diverse application conditions.

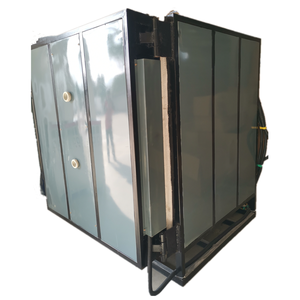

(China 200 T/d Activated Lime Rotary Kiln)

Specifications of China 200 T/d Activated Lime Rotary Kiln

This China-made 200 ton daily Triggered Lime Rotary Kiln provides a trustworthy solution for creating top quality lime. It refines 200 statistics tons of sedimentary rock daily. The kiln includes a robust design built for continual procedure. Its rotating cylinder design guarantees exceptional product blending. This mixing promotes also home heating and consistent calcination. The kiln body utilizes thick steel plates. These plates offer architectural stamina and lengthy service life. Top-quality refractory bricks line the inner chamber. This lining withstands extreme warm and protects the steel shell. It handles limestone feed dimensions efficiently. Proper sizing aids achieve complete calcination. The kiln runs at meticulously regulated temperature levels. These temperature levels maximize the calcination procedure. This process changes limestone into responsive quicklime. The kiln system includes a preheater section. This section utilizes exhaust gases to preheat incoming limestone. Pre-heating boosts thermal efficiency dramatically. It lowers overall fuel intake. The kiln also integrates a cooler unit. The cooler cools down the hot lime product using ambient air. This recuperated warmth further boosts energy savings. The cooled down lime is after that prepared for storage. The layout prioritizes ease of procedure and maintenance. Operators discover the controls straightforward. Accessibility points simplify assessment tasks. Regular upkeep is manageable. The kiln attains high lime conversion prices. It generates lime meeting stringent activity standards. This lime appropriates for requiring commercial usages. Users take advantage of low operating expense. Power performance equates directly right into financial savings. The kiln supplies trusted performance year-round. It takes care of continual manufacturing needs well. Downtime is minimized through strong building. This equipment supplies regular product top quality output.

(China 200 T/d Activated Lime Rotary Kiln)

Applications of China 200 T/d Activated Lime Rotary Kiln

This 200 ton per day turned on lime rotating kiln from China makes high-grade quicklime. Manufacturing facilities need this lime for many crucial jobs. Steel plants make use of large quantities of triggered lime. They add it to thaw iron and steel. This removes sulfur. It cleanses the metal. Great desulfurization makes stronger, better steel. Metallurgical manufacturing facilities likewise rely on this lime. It assists fine-tune non-ferrous steels like copper, zinc, and aluminum. The lime obtains contaminations. It detoxifies the steel. Chemical plants utilize turned on lime also. It is a basic resources. They make calcium carbide, soft drink ash, and whitening powder with it. Several other chemicals begin with lime. Nuclear power plant and waste incinerators need this lime. They utilize it to tidy flue gases. The lime secures sulfur dioxide and other acid gases. This lowers air pollution. It satisfies ecological guidelines. Building and construction material business get activated lime. They make oxygenated cinder block and lime sand bricks. These building products require regular lime. Other markets likewise count on this kiln’s result. Paper mills use lime in pulping and lightening procedures. Sugar refineries detoxify juice with it. Water therapy plants adjust pH and remove solidity making use of lime. This 200 T/D rotary kiln offers a constant supply. It is dependable for continuous commercial operations. Companies select it for secure manufacturing. It aids them regulate prices. The kiln layout ensures effective burning. It makes pure, extremely responsive lime. This is vital for effective usage in all these applications. The equipment is developed challenging. It takes care of the rough problems of lime calcination well. Manufacturing facilities get the item high quality they need.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of China 200 T/d Activated Lime Rotary Kiln

What is a 200 T/d Activated Lime Rotary Kiln?

It is a large industrial furnace shaped like a tube. It rotates slowly. The kiln heats limestone to very high temperatures. This process is called calcination. It turns limestone into activated lime powder. The “200 T/d” means it can produce 200 tons of lime powder every single day.

How does the kiln ensure good lime quality?

The kiln controls temperature precisely. It keeps a stable heat profile inside. Good temperature control is crucial. It affects how reactive the final lime powder is. We use reliable burners. We use accurate temperature sensors. This ensures consistent heating. The lime quality meets industry standards. It performs well in applications.

Is this kiln energy efficient?

Yes. The design focuses on saving energy. It uses good insulation materials. Heat loss is minimized. Special heat exchangers may be used. These recover heat from exhaust gases. This heat preheats incoming limestone. Less fuel is needed. Operating costs are lower.

How often does the kiln need maintenance?

Regular checks are important. Daily visual inspections happen. Weekly checks focus on key moving parts. Monthly checks are more thorough. They cover refractory lining wear. They check mechanical components. Proper lubrication is essential. Planned shutdowns allow major inspections. Timely maintenance prevents big problems. It keeps the kiln running smoothly.

Can the kiln be customized?

Yes. Customer needs vary. We can adjust the kiln length and diameter slightly. Different burner types are available. Fuel options include gas, coal, or oil. Advanced control systems can be added. Refractory materials might be chosen based on local limestone. We discuss your specific requirements. We offer solutions that fit.

(China 200 T/d Activated Lime Rotary Kiln)

REQUEST A QUOTE

RELATED PRODUCTS

Lab Testing Kiln Small Rotary Kiln for Samples Calcination and Sintering

Vertical Mill Spare Parts Grinding Mill Roller Sleeve Cast Iron Vertical Mill Roller Sleeve

Small Scale Solid Waste Incinerator Rotary Kiln for / Cement Kiln for / Cement Kiln

Rotary Kiln Shaft kiln Iron Technology Iron Ore Oxide Pelletizing Plant Iron Ore Pellet Plant

Rotating oven of gypsum kiln for plaster calcining magnesium oxide rotary kiln