PRODUCT PARAMETERS

Description

Introduction to Factory mineral powder dryer/ waste plastic drying equipment/ sand rotary dryer

Factory mineral powder dryer/ waste plastic drying equipment/ sand rotary dryer is for repairing, replacing or upgrading worn, damaged or deteriorated parts in drying equipment. These spare parts can include heating elements, drums, belts, fans, temperature and humidity controls, etc., to ensure that the dryer will run efficiently and consistently.

Advantages and features of Factory mineral powder dryer/ waste plastic drying equipment/ sand rotary dryer

High-quality materials: manufactured using durable and heat-resistant materials to ensure long life and high reliability.

Precise Fit: Precisely designed for specific models of dryers to ensure easy installation and perfect fit.

Rapid Response: Provide fast spare parts supply service to reduce downtime and improve production efficiency.

Technical Support: Equipped with a professional technical support team to provide installation guidance and troubleshooting assistance.

Cost-effectiveness: Reduce long-term operating costs by extending the service life of the equipment.

(Factory mineral powder dryer/ waste plastic drying equipment/ sand rotary dryer)

Specifications of Factory mineral powder dryer/ waste plastic drying equipment/ sand rotary dryer

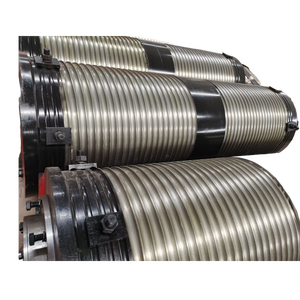

Our mineral powder dryer handles fine materials efficiently. It uses hot air for drying. This dryer works continuously. The drum rotates slowly. Heat transfers evenly through the powder. Materials don’t stick or burn easily. We build it with stainless steel inside. This prevents corrosion. The temperature stays controlled. This protects the material quality. Output capacity ranges from 500kg to 10 tons per hour. It suits minerals like quartz, limestone, and gypsum powder. The system includes dust collectors. This keeps the air clean. Energy consumption is low. This saves money.

For waste plastic drying, our equipment is heavy-duty. It handles wet flakes, pellets, or pieces. Hot air flows through the material bed. The drum has special lifters. These turn the plastic constantly. Drying happens fast and uniformly. Moisture removal is thorough. The heating source can be gas, oil, or electricity. We use thick carbon steel construction. This withstands tough use. Safety is important. We include spark detection and suppression systems. Temperature sensors prevent overheating. Capacities go from 1 ton to 15 tons each hour. It works for PET, PP, PE, and other plastics.

The sand rotary dryer is built for bulk drying. It processes large amounts of wet sand quickly. The long, rotating drum is the key part. Heated air moves through it. Sand tumbles inside. This exposure ensures even drying. We use heat-resistant steel. This handles abrasion well. The system adjusts for different sand types. Moisture levels drop below 1%. Output is high, from 5 tons to 50 tons per hour. It fits construction sand, foundry sand, or river sand. The design prevents sand from sticking. Maintenance is simple. Fuel options are flexible.

(Factory mineral powder dryer/ waste plastic drying equipment/ sand rotary dryer)

Applications of Factory mineral powder dryer/ waste plastic drying equipment/ sand rotary dryer

Factory mineral powder dryers handle many fine materials. Gypsum powder needs drying before making wallboard. Cement plants dry raw mineral powders efficiently. Ceramic factories use these dryers for clay and other powders. The equipment prevents clumping during drying. It keeps the powder flowing smoothly. Consistent drying is vital for quality products. This dryer type suits heat-sensitive powders well. It offers precise temperature control.

Waste plastic drying equipment is key for recycling. Washed plastic flakes often hold too much water. This dryer removes that moisture fast. It prepares plastic for pelletizing or new products. Different plastics need different drying temperatures. The equipment handles this safely. It ensures the plastic is dry enough. Moisture ruins recycled plastic quality. This dryer prevents that problem. It works with flakes, shreds, or granules.

Sand rotary dryers are tough machines. They dry large amounts of bulk sand effectively. Construction sand must be dry for concrete mixing. Foundry sand needs drying before metal casting. These dryers handle coarse, abrasive materials daily. The rotating drum tumbles the sand constantly. Hot air flows through the tumbling sand. This contact dries the sand quickly and evenly. High moisture sand causes problems. This dryer solves that issue. It’s built for heavy, continuous use.

Company Introduction

Established in 2001, plant Machinery Equipment Co.,ltd. focus on metal research and mining machinery spare parts. 2 factories over an area of 13,300 square meters, based on 100+ sets of equipment, our production capacity reaches 12000 Tons/Year. has passed ISO 9001 quality managment system certification in 2008.

Our mainly products are dragline excavator spare parts,rotary kiln spare parts, large modulus gear (gear shaft), gearbox ect. 40+ patents with over 45 years experience to help focus on improve the service life of spare parts. We belive that more than 80% reason of mechanical parts’ working life depends on hot processing (steel making/forging/casting/welding/heat treatment). Eight material engineers will control the quality from the original resource.

If you are interested, please feel free to contact us.

Payment

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

5 FAQs of Factory mineral powder dryer/ waste plastic drying equipment/ sand rotary dryer

What does this dryer handle?

It handles mineral powder, plastic flakes, sand. Different materials need different settings. The machine adjusts. Wet material goes in. Dry material comes out.

How does drying happen?

Hot air flows through a rotating drum. The material tumbles inside. This action exposes all pieces to the heat. Moisture evaporates. The process is continuous. Material moves from one end to the other.

Will it damage plastic flakes?

No. The heat is controlled carefully. Gentle tumbling prevents melting or clumping. Plastic flakes stay separate. They dry evenly. The system protects sensitive materials.

Is it expensive to run?

Running costs are reasonable. The design uses heat efficiently. Good insulation keeps heat inside the drum. Less energy is wasted. This lowers fuel bills.

What upkeep is needed?

Regular checks are essential. Bearings and seals need lubrication. Motors need inspection. The drum interior should be cleaned periodically. This prevents material buildup. Simple maintenance keeps it running smoothly.

(Factory mineral powder dryer/ waste plastic drying equipment/ sand rotary dryer)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Industrial 1 To 20 Tons Per Hour Sawdust Rotary Dryer

High quality Dryer parts Electric Dryer Heating Element 3387747 Heating parts 3387747

Good Rotary Drum Drying Machine Morocco Slag Sand Salt Industrial Dryer For

Rotary drum dryer for Pregelatinized starch process

New Type Energy Saving Industrial single cylinder Drying Equipment Rotary Drum Dryer